29.06.2025 by Viktor Siebert

Damaged Bearings Due to Coolant Ingress in Mitsubishi HF75BS-A48 AC Servo Motor

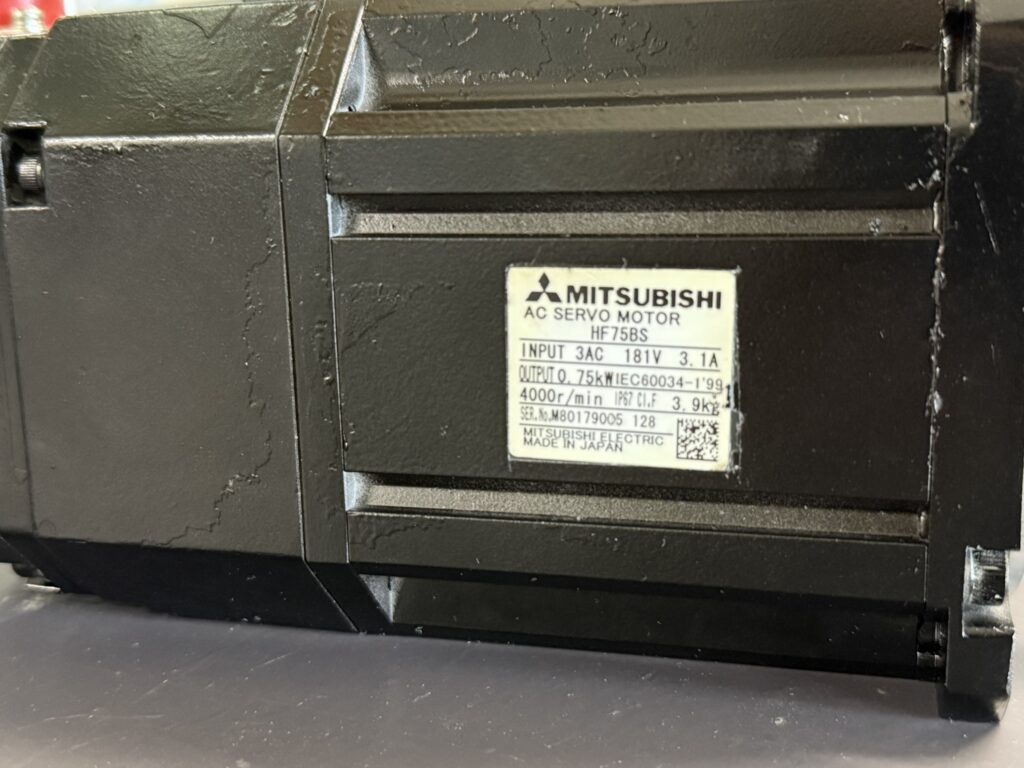

We recently received several Mitsubishi HF75BS AC servo motors for refurbishment. All of them exhibited the same type of damage: destroyed bearings, contaminated brakes, and in some cases defective encoders. The root cause: coolant had penetrated into the motor housing.

How Coolant Enters the Motor

In machining environments, coolant is rarely a pure fluid. It’s often a highly aggressive mix – containing chips, oils, dust, and abrasive particles. When this mixture infiltrates the inside of a motor, it can chemically and mechanically destroy internal components.

The most common entry point is through aging seals. Over time, these become brittle and porous. In high-duty machines or with poor maintenance, the emulsion finds its way into the motor.

Typical Damage Caused by Fluid Ingress

- Bearings: First to fail due to their exposed position. Coolant washes out lubrication, leads to corrosion, and ultimately results in bearing failure.

- Rotor: Abrasive particles damage the rotor surface, causing imbalance and noise.

- Brake: Often soaked in fluid, but still mechanically intact – and therefore recoverable in our facility.

- Encoder: Usually well-sealed and last to be affected. Two out of the three motors we received had defective encoders.

Why Replacing the Encoder Is Not That Simple

Many assume they can simply order a new encoder from Mitsubishi and install it. The reality is different: Mitsubishi delivers blank encoders, which are unprogrammed units. These need to be custom-configured to match the specific motor model – a service Mitsubishi often cannot provide promptly.

Our Solutions for Encoder Issues

Over the years, we have developed two reliable strategies:

- Replacement with Parameterized Encoder: We receive raw encoders and program them with the correct motor data. This includes:

- Pole pair configuration

- Zero-pulse position

- Communication protocol settings

- Refurbishment of Existing Encoder: If the original PCB is still intact, we refurbish the encoder at both mechanical and electronic levels:

- Polishing the optical glass disc

- Cleaning and aligning the LED reader assembly

- Replacing worn components and connectors

- Recalibrating the output signals

The result is a high-quality refurbished encoder, often close to the performance of a new one.

How the OBA18 Serial Optical Encoder Works

The OBA18 is a high-precision serial optical encoder. It converts rotational movement into digital signals using an internal glass code disc and LED sensor system.

Function and Structure:

- Glass Code Disc: Microscopic light/dark patterns are etched onto a glass disc.

- LED Reader: An infrared LED shines through the disc; light transmission varies based on position.

- Photodiode Array: Detects the light signal and converts it into pulses.

- Signal Processing: The encoder electronics convert these signals into serial communication outputs. Calibration ensures the zero-pulse is synchronized and accurate.

Our Overhaul Process in Detail

All three motors were fully overhauled using the following steps:

- Complete disassembly and cleaning of all components

- Bearing replacement using precision-grade bearings matched to the application

- Rotor restoration: removal of corrosion, surface reconditioning, and dynamic balancing

- Brake regeneration after internal decontamination

- Seal replacement with improved modern materials

- Encoder refurbishment or replacement with full test

- Comprehensive final testing on our in-house test rigs, including:

- Vibration analysis

- Noise inspection

- Brake torque testing

- Encoder signal evaluation under load

Our Testing Process – Like the OEM

Our motors undergo a multi-step inspection and test sequence that mirrors the procedures used by the original manufacturer. On our custom-built test benches, we simulate real-world machine conditions and validate:

- Start-up behavior under load

- Positioning precision

- Temperature response

- Encoder signal integrity

- Brake performance under dynamic conditions

Finally, all measured values are documented in a test report to ensure a reliable and traceable motor return to the customer.

To mentioned Mitsubishi Motor: Mitsubishi HF75BS-A48 AC Servo Motor

More details about our Mitsubishi repair services can be found here:

Mitsubishi motor Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications (from nameplate and standard references)

| Specification | Value |

|---|

| Model | Mitsubishi HF75BS |

| Motor Type | AC Servo Motor (Brushless) |

| Input Voltage | 3-phase AC 181 V |

| Rated Current | 3.1 A |

| Output Power | 0.75 kW |

| Rated Speed | 4000 rpm |

| Protection Rating | IP67 |

| Weight | Approx. 3.9 kg |

| Compliance | IEC60034 |

| Insulation Class | Likely F |

| Serial Number | M80179005 |

| Manufacturer | Mitsubishi Electric, Japan |

Functional Description

The Mitsubishi HF75BS is a brushless AC servo motor designed for precision motion control. It works in closed-loop systems in combination with a servo amplifier (e.g., Mitsubishi MR-J2S or MR-J3 series).

Key Features:

- Position and speed feedback via an integrated encoder (typically serial optical, such as the OBA18).

- High dynamic response, suitable for fast positioning and acceleration/deceleration cycles.

- Compact design, ideal for tight installation spaces.

- IP67 protection, meaning fully dust-tight and resistant to temporary submersion – suitable for coolant-rich environments like CNC machines.

Typical Applications

These motors are commonly used in the following types of machinery:

| Machine Type | Typical Use Case |

|---|

| CNC Machines (milling, turning centers) | Feed axes, linear/rotary axis control |

| Packaging Equipment | Precise axis positioning, cutting stations |

| Industrial Robotics | Joint actuation, high-precision movements |

| Semiconductor Manufacturing | Controlled motion under cleanroom conditions |

| Printing & Labeling Machines | Register control, cutting heads |

| Assembly Lines (e.g. automotive) | Lifting, rotating, gripping mechanisms |

Alarms and Troubleshooting

| Alarm Code | Description | Possible Cause | Solution |

|---|

| 50 | Overload protection triggered | Prolonged overload | Check load, run diagnostics |

| 51 | Max current exceeded | Blockage, short circuit | Inspect mechanics and cables |

| A.10 | Overcurrent | IGBT or cable fault | Check insulation, test motor |

| A.32 | Overheat (motor or brake) | Blocked ventilation, brake fault | Clean fan, replace brake |