06.09.2025 by Viktor Siebert

Mitsubishi MDS-B-CV-370 Power Supply Unit Analysis, Repair & Prevention

A customer reported repeated sudden shutdowns of his CNC machine. The MDS-B-CV-370 Power Supply Unit showed no signs of life, no LEDs lit up, no relay engaged. The failure occurred randomly, making stable production impossible.

During initial inspection, the device was visually examined. Heavy dust deposits, aged fans, and a discolored power board gave first clues: thermal stress and lack of preventive maintenance. After disassembly, a detailed cleaning process was performed. It became clear that several DC link capacitors were swollen and at risk of failure.

Step-by-step repair process:

- Cleaning –> complete removal of dust, oil residues, and emulsions.

- Preventive replacement –> all DC link capacitors, ICs, relays, and cooling fans were replaced.

- Diagnostics –> the control board was checked for conductor interruptions, critical solder joints were reworked.

- Insulation tests –> verification of leakage currents, especially at the DC bus.

- Load testing –> operation on a dedicated test bench with dummy loads simulating real machine conditions.

- Thermal stress test –> continuous some hours operation under full load to ensure long-term stability.

Checklists & Documentation: Every repair step was logged, measurements were recorded, and all replaced components were documented to guarantee traceability for future service events.

Result: The power supply unit was successfully repaired and returned to the customer. Once reinstalled in the CNC machine, the system operated stably without further failures.

Preventive Measures for Customers

- Regular cleaning of dust and oil residues

- Replacement of cooling fans every 3–5 years

- Insulation tests of motors and cables

- Inspection of seals to prevent ingress of coolant and moisture

- Scheduled maintenance intervals with proper documentation

Conclusion

The repair of the MDS-B-CV-370 demonstrates the importance of preventive maintenance. Timely replacement of wear components and systematic cleaning significantly reduce the risk of costly failures. Customers benefit from improved machine uptime, stable processes, and predictable operating costs.

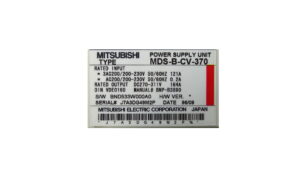

To mentioned Mitsubishi Drive: Mitsubishi MDS-B-CV-370 Power Supply Unit

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Type | MDS-B-CV-370 |

| Rated Input | 3AC 200/200–230V, 50/60Hz, 121AAC 200/200–230V, 50/60Hz, 0.2A |

| Rated Output | DC 270–311V, 164A |

| Standard | DIN VDE0160 |

| Manual No. | BNP-B3890 |

| Date of Manufacture | 09/1996 |

| Manufacturer | Mitsubishi Electric Corporation, Japan |

Application Environment & Compatible Devices

The MDS-B-CV-370 Power Supply Unit is typically used in CNC machine tools that require high power reserves.

Common applications include lathes, milling machines, and machining centers from manufacturers such as DMG Mori, Mazak, Traub, and Hitachi Seiki.

It is compatible with the MDS-B series drive amplifiers and reliably supplies axis and spindle drives with stable DC bus voltage.

Functional Description

The power supply unit converts the three-phase AC input into a regulated DC bus voltage. This DC voltage is then supplied to the connected servo and spindle amplifiers.

Main functions:

- Conversion of AC → DC

- Protection of the control system against voltage fluctuations

- Monitoring of phase loss, overcurrent, and overheating

- Provision of diagnostic and alarm messages

Alarms and Troubleshooting

| Alarm No. | LED | Name | Meaning | Remedy |

|---|

| 61 | 1 | Power module error | Overcurrent in the power module (IPM) detected | Check/replace module |

| 63 | 3 | Compensation regeneration | Regenerative transistor active too long | Check regenerative circuit |

| 65 | 5 | Rush relay error | Rush relay did not switch correctly | Replace relay |

| 67 | 7 | Open phase | One of the input phases (R, S, T) is missing | Check power supply line |

| 68 | 8 | Watch dog | Software process did not complete | Restart controller |

| 69 | 9 | Ground fault | Ground fault in the motor | Check insulation |

| 6A | A | Contactor melt | External contactor failed | Replace contactor |

| 6B | B | Rush relay melt | Rush relay shorted or stuck | Replace relay |

| 6C | C | Main circuit error | Error in the main capacitor charging circuit | Inspect main circuit |

| 71 | H | Emergency stop | External emergency stop activated | Eliminate cause, reset |

| 75 | L | Overvoltage | Voltage between P and N exceeded 410V | Check supply voltage |

| 77 | n | Power module overheat | Overheating in the power module (IPM) | Check cooling, replace fans |

Components

| Type | Designation | Qty |

|---|

| Control board | RK412A or BN634A770G51 B | 1 |

| Power board | RK432 or BN634A783G51 B | 1 |

| DC link capacitor board | RK443A-370 or BN634A784G51 | 1 |

| Power module | Power module | 1 |