22.06.2025 by Viktor Siebert

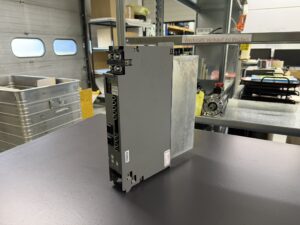

Repair of an Okuma Servo Drive MIV0101-1-B1 1006-2224

A customer contacted us because repairing a failed Okuma Servo Drive MIV0101-1-B1 seemed more economically beneficial and sustainable compared to purchasing a new unit. A replacement device would have cost more than €5,000, and the delivery time for the new unit would not have been significantly shorter than the repair duration.

Quality Assurance – Our Promise to Customers

Quality is our top priority. Every repair job, including the MIV0101-1-B1, follows clearly defined procedures:

- Initial Inspection and Fault Diagnosis: Our experienced technicians conduct a thorough visual and electronic inspection to precisely identify the cause of failure using advanced diagnostic tools.

- Preventive Overhaul: We proactively overhauled the device, replacing all components identified as critical or prone to frequent failures over the years. Specifically, all electrolytic capacitors were replaced, the power output stage was repaired, and optoelectronic chips as well as current and voltage measurement modules were replaced.

- Comprehensive Long-term Testing: Before delivery, we conduct long-term testing in an original Okuma machine to ensure full functionality and reliability of the unit.

Sustainability – Repair Instead of Disposal

Sustainability is more important than ever. Many companies are increasingly aware of responsible resource management. We actively support this goal:

- Resource Conservation through Repairs: Instead of replacing failed devices and thereby wasting resources, we deliberately choose repairs. This approach prevents unnecessary electronic waste and reduces environmental impact.

- Extending Equipment Lifespan: Our high-quality repairs significantly extend the lifespan of industrial equipment, saving costs and contributing substantially to a sustainable economic cycle.

Successful Completion and Satisfied Customers

Following the thorough repair and comprehensive quality checks, the device was promptly returned to the customer. Production could quickly resume, and the customer was delighted with our cost-effective and sustainable solution.

Our goal remains clear: maximum quality, highest reliability, and sustainable practices for the benefit of our customers and the environment.

Price and Delivery Time for Okuma Servo Drive MIV0101-1-B1

For more information about our Okuma repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Mitsubishi drive technology. Our experienced team is always ready to provide you with expert advice and support.

Technical Specifications (Device Data):

| Property | Value |

|---|

| Power | 1.0 kW (1.33 hp) |

| Control Board | Type ICB1 |

| Motor Type | BL motor, PREX motor |

| ROM Type | Type 1 |

Operating Environment and Associated Devices:

The MIV unit typically operates in CNC-controlled machine tools and industrial robots. It controls BL or PREX motors and closely collaborates with Okuma spindle drives and NC controllers. Common usage occurs in industrial environments with controlled temperature, humidity, and vibration conditions.

Functional Description:

The MIV unit functions as an inverter, modulating electrical energy to precisely control servo motors. It converts DC voltage from the power supply into variable frequency and voltage, which is essential for controlling motor speed and torque. Precise control is managed through an integrated control board (ICB1) coordinating power and communication processes.

Alarm Messages and Troubleshooting:

Here are some critical alarms with possible causes and troubleshooting measures (selected details):

| Alarm No. | Alarm Name | Possible Cause | Corrective Action |

|---|

| 01 | Power Supply Unit Error | DC/AC voltage alarm, control power error, CPU error | Check power supply voltage, replace MIV unit |

| 03 | Inverter DC Bus Voltage Error | DC bus voltage too high/low | Check power supply voltage, replace MIV unit |

| 04 | Motor Power Line Overcurrent | Overcurrent detected in motor | Replace motor or MIV unit |

| 05 | Inverter Overheat | Excessive inverter temperature | Check operating conditions, replace MIV unit |

| 06 | Inverter Overload | Electronic thermal relay activated | Reduce load torque, adjust conditions |

| 10 | Encoder Communication Error | Communication error with encoder | Inspect/replace cables, replace encoder |

| 20 | Motor Overheat | Motor temperature excessively high | Check operating conditions, replace motor |

| 31 | Speed Over | Actual speed too high | Replace encoder/motor, check cable connections |

Unit Components:

| Component | Board Designation |

|---|

| Control Board | ICB1 |

| Power Board | IVPB0101 |

| Connection Board | E4809-045-209A |

| Power Module | MIV0303 |