28.10.2025 by Viktor Siebert

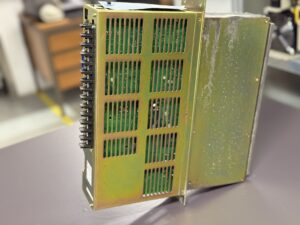

Repair of a Yaskawa CACR-IR15SEB AC Servopack

Repair and Testing Description

The CACR-IR15SEB Servopack was sent in with Alarm 3 Regenerative Problem Detection. According to the customer, the fault occurred sporadically, but when tested in our workshop, it appeared immediately after startup, which made the diagnosis much easier.

After removing the cover, a visual inspection of the power and control sections was carried out. A leaking electrolytic capacitor was clearly visible on the control board. The spilled electrolyte had spread across multiple tracks, causing corrosion and interrupting critical signal paths and logic lines in the CPU section. As a result, the regeneration circuit was no longer functioning correctly.

An attempt was made to clean and locally repair the damaged area, but the result was unstable. The internal processor and several SMD components were already permanently damaged. In most cases, such boards can only be repaired to a limited extent because calibration and control parameters are individually tuned to each amplifier unit.

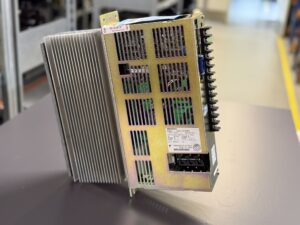

Fortunately, our workshop maintains a large stock of original Yaskawa boards and spare parts. A compatible control board was identified, adapted, and reprogrammed. During replacement, it was essential to transfer the parameter set from the original unit to ensure identical behavior. After installation, the unit was fully re-initialized, and the offset and reference values were recalibrated.

Several test runs followed on our dedicated Yaskawa test stand. The Servopack was operated with a reference motor in different modes torque, speed, and position under varying load conditions. The drive performed perfectly, and no further alarms were detected.

As part of our preventive service process, all electrolytic capacitors were replaced, the gate driver circuit was verified, thermal paste was renewed, and both the fan and filter section were checked. After a 24-hour burn-in test at elevated ambient temperature, the unit passed final inspection. Voltage readings and regenerative performance were stable throughout the test.

The customer was informed about the root cause a leaking capacitor that had destroyed the control board. Despite additional costs for the new control board, the customer approved the repair, as the unit was essential for production.

After reinstallation in the machine, the Servopack operated flawlessly and has remained stable without recurring errors.

To mentioned Yaskawa Drive: Yaskawa CACR-IR15SEB AC Servopack

More details about our Yaskawa repair services can be found here:

Yaskawa drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Overview

The Yaskawa CACR-IR15SEB Servopack is a high-performance AC servo amplifier from the IR series, designed for precise motion control in industrial applications. The series was developed to provide high dynamics, accuracy, and long-term reliability.

Due to its regenerative circuit, excess energy is returned to the mains, improving overall efficiency. The unit is solidly built and still widely used in older CNC machines, tool changers, and automation systems.

- Device category: AC servo amplifier

- Series: CACR-IR (Regenerative Type)

- Design: Compact, forced-air cooled

- Manufacturer: Yaskawa Electric, Japan

Model Description

- CA = Controller Amplifier

- CR = Regenerative Type

- IR15SEB = 1.5 kW version, three-phase input, 200-230 V class

Technical Data

| Parameter | Description |

|---|

| Model | CACR-IR15SEB |

| Manufacturer | Yaskawa Electric (Japan) |

| Input voltage | 200 – 230 V AC, 3 phase |

| Frequency | 50 / 60 Hz |

| Input current | 10 A |

| Output voltage | 0 – 230 V AC, 3 phase |

| Output current | 11.7 A |

| Output power | 1.5 kW (2.01 HP) |

| Cooling | Forced air cooling |

| Weight | Approx. 6.5 kg |

| Year of manufacture | Approx. 1996 – 1999 |

| Features | Regenerative circuit, LED alarm indicator, galvanic isolation, robust metal construction |

Connections

| Terminal | Function |

|---|

| R / S / T | 3-phase power input |

| U / V / W | Motor output |

| CN1 | Control and feedback interface |

| CN2 | Encoder and communication connector |

| CN3 | Brake control / external interface |

| E1-E3 | Ground terminals (GND) |

Internal Boards and Modules

| Assembly | Description |

|---|

| Power Board | Main power stage with regenerative circuit |

| Control Board | Control logic and CPU regulation |

| Gate Drive Board | IGBT driver control |

| Feedback Interface | Encoder and feedback signal processing |

| Filter Section | Line filter and DC bus capacitors |

| Fan Unit | Cooling of the power section |

Typical Alarms and Solutions

(based on Yaskawa CACR-IR Servo Alarms Indicator Manual, NC93-968, pages 2 – 5)

| Code | Name | Description | Cause | Action |

|---|

| 1 | Overcurrent Detection | Overcurrent in the main circuit | Short circuit or defective transistor | Check insulation, test power module |

| 2 | MCCB Trip Detection | Motor circuit breaker tripped | Overload or faulty MCCB | Check wiring and MCCB |

| 3 | Regenerative Problem Detection | Regeneration circuit malfunction | Fault in regenerative module or control section | Inspect regeneration and control circuits |

| 4 | Overvoltage Detection | Excess voltage in DC bus | Regeneration or line surge | Check DC bus capacitors |

| 5 | Insufficient Voltage Detection | Undervoltage in main circuit | Low supply voltage or defective rectifier | Verify power supply |

| 6 | Ground Fault Detection | Ground fault in main circuit | Damaged insulation | Check motor wiring and insulation |

| 7 | Current Offset Problem | No or incorrect current offset | Drift or offset circuit issue | Recalibrate measurement circuit |

| 8 | Current Command Disconnection | Current command signal interrupted | Broken control cable | Inspect signal connection |

| 9 | Open Phase Detection | One phase missing | Phase loss in power input | Check phase supply |

| F | CPU Problem Detection | Abnormal CPU | Faulty control board | Replace or repair CPU board |

Typical Applications

- CNC machine tools (milling, turning)

- Automatic tool changers

- Feed drives and positioning systems

- Industrial automation units

Service and Maintenance Notes

- Check electrolytic capacitors regularly (service life approx. 5 – 7 years)

- Clean fans and heat sinks to ensure proper airflow

- Replace corroded or electrolyte-damaged control boards completely

- Perform parameter calibration and offset adjustment after board replacement

- Always use genuine Yaskawa spare parts for reliability and compatibility