05.09.2025 by Viktor Siebert

Mitsubishi MDS-C1-V1-20 Servo Drive Unit Analysis, Faults and Repair

A customer from France reported a serious issue: the machine was intermittently triggering Alarm A.32 (Power Module Overcurrent).

Each time, a tool crash occurred, after three crashes, production losses had already escalated to a critical level.

The customer tried everything within reach: swapping motors, control boards, and cables. None of these measures solved the problem.

When he finally contacted the machine manufacturer, he was told that the drive module would have to be replaced at a cost of several thousand euros. On top of that, he was charged an additional €1200 for the technician’s travel expenses, as the technician had to travel nearly 500 km to the site.

Frustrated, the customer turned to us after receiving a recommendation. We were already familiar with this device, and with this type of fault.

Our diagnosis was clear: the intermittent A.32 alarm pointed to a thermally stressed IPM (Intelligent Power Module) inside the drive.

Our repair process included:

- Initial testing on our dedicated test bench with full axis load simulation

- Thorough cleaning: removal of dust, coolant, and oil residues

- Preventive replacement of the IGBT modules and driver ICs

- Inspection of the control board and recalibration of measurement circuits

- Thermal stress testing under nominal load for several hours

- Detailed documentation of every step using checklists and protocols

After just four days, the repaired unit was shipped back.

The customer was able to resume production immediately avoiding the huge costs of module replacement and unnecessary travel expenses.

Preventive Measures for Customers

To extend the service life of such units, we recommend:

- Regular cleaning of fans and heat sinks

- Fan replacement every 3–5 years

- Insulation testing of motor cables

- Inspection of connectors for oil or dust contamination

- Checking seals to prevent coolant or emulsion ingress

Conclusion

The Mitsubishi MDS-C1-V1-20 Servo Drive Unit is a reliable drive, but prone to thermal and electrical stress if maintenance is neglected.

With preventive measures and professional repair, failures can be minimized and costly downtime avoided.

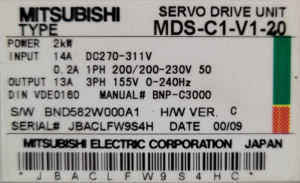

To mentioned Mitsubishi Drive: Mitsubishi MDS-C1-V1-20 Servo Drive Unit

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Type | MDS-C1-V1-20 Servo Drive Unit |

| Power | 2 kW |

| Input | 14 A, DC 270–311 V |

| Auxiliary Input | 0.2 A, 1 Phase, 200/220–230 V, 50 Hz |

| Output | 13 A, 3 Phase, 155 V, 0–240 Hz |

| Weight | approx. 7–8 kg (estimated) |

| Year | 2009 |

| Manual Reference | BNP-C3000 |

| Manufacturer | Mitsubishi Electric Corporation, Japan |

Application Environment & Compatible Devices

The MDS-C1-V1 series is widely used in CNC machine tools such as Mazak, DMG Mori, and Traub.

Its role is to precisely control AC servo motors, typically for axis drives in milling and turning machines.

Typical environments include:

- High-precision machining centers

- Multi-axis lathes

- Automated production lines

Compatible motors are Mitsubishi HA and HF series.

Functional Description

The MDS-C1-V1-20 Servo Drive Unit supplies and controls servo motors up to 2 kW.

Its functions include:

- Converting DC bus voltage into motor supply

- Accurate control of motor phase currents

- Monitoring feedback and error detection (encoder, overcurrent, overheating)

- Communication with CNC controllers (Mazatrol, Meldas, etc.)

The robust design allows continuous operation in demanding industrial environments, but preventive maintenance is essential.

Alarm Messages and Troubleshooting

Selected alarms from the MDS-C1 manual:

| Alarm | Meaning | Cause | Remedy |

|---|

| 12 | Memory error | Error in SRAM/FLROM | Replace unit, check environment |

| 17 | A/D converter error | Fault in A/D converter | Replace drive |

| 21 | No signal 2 | Feedback signal missing | Check cables, encoder |

| 25 | Absolute position lost | Absolute value lost | Check battery or cables |

| 32 | Power module overcurrent | IPM detected overcurrent | Check motor, wiring, power module |

| 42 | Feedback error 1 | U/V/W feedback signal error | Replace cables/encoder |

| 46 | Motor overheat | Motor temperature too high | Check fan, cooling |

| 50 | Overload 1 | Motor current overload | Verify parameters, load |

| 51 | Overload 2 | Continuous overload condition | Inspect motor and drive |

| 58 | Collision detection 1 | Axis collision detected | Inspect machine mechanics |

| 70 | AC input error | AC phase failure | Check supply lines |

Components

| Type | Board Designation | Qty |

|---|

| Control Board | RK112A-21 / BN634A980G51 B | 1 |

| Power Board | RL122B-V1 / BN638A153G51 A | 1 |

| Power Module | BKO-NC1207 H91 A2-V1-20 | 1 |