28.06.2025 by Viktor Siebert

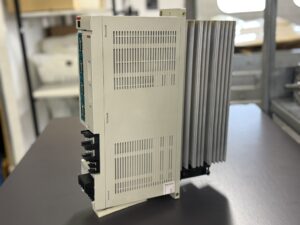

Prevention Is Better Than Cure – Why Servo Drives Fail Sooner Than Expected Mitsubishi Servo Drive MDS-CH-V2-4535

We recently received a Mitsubishi MDS-CH-V2-4535 Servo AC Drive for repair. The customer reported that the drive would suddenly shut down at higher speeds. Under load, it couldn’t even reach 50% before triggering an Overload error.

At first, this was surprising. The drive had only been in operation for about three years, replacing a previous unit that had failed in a similar way. But why did this new drive fail so early?

Three Years of Operation – Not an Issue Under Normal Conditions

Our engineers confirmed: These servo drives are built for long-term, industrial use. A lifespan of 10 to 15 years is not unusual when used in a proper environment and maintained regularly. Failing after just three years indicates something more than simple aging.

So what happened?

The Root Cause: Dirt, Dust, and Neglected Maintenance

After contacting the customer, our technical sales engineer dug a bit deeper. The truth came out:

- When the previous unit failed, no cleaning or inspection was done.

- The new module was simply plugged into the same dirty electrical cabinet.

- The machine was about 12–15 years old, and although clean on the outside, the inside told a different story.

- Dust, oil mist, and chips were present throughout the electrical enclosure.

- Cooling fans and air passages were clogged.

- Neighboring components were equally dirty.

This means the new drive was exposed to the same thermal stress as its predecessor from day one. Over time, the power transistors, gate drivers, and capacitors degraded far quicker than normal – because they were not able to cool properly.

What We Did During the Repair

Our repair process followed a comprehensive technical workflow:

- Complete cleaning of internal components, cooling ducts, and PCBs

- Replacement of thermally stressed parts: IGBT modules, snubbers, gate drivers

- Installation of a new fan unit

- Re-soldering of high-current paths

- Final tests under real-world load conditions using our in-house servo drive test benches

- Thermographic analysis to validate stable heat dissipation

The unit was restored to like-new condition and passed all performance and thermal tests.

What the Customer Should Have Done Differently

1. Don’t Judge by the Outside

The enclosure might look clean – but check the inside. Over time, CNC cabinets collect layers of conductive grime.

2. Clean Fans and Filters Annually

Blocked airflow is the most common reason for overheating. At least once per year, clean or replace fans and filters.

3. Never Install New Electronics in a Dirty Cabinet

Inserting a new drive into an old, dirty system is like putting a new engine in a car with clogged radiators.

4. Include Surrounding Components

Even if one unit is new, the airflow and contamination affect all devices inside the cabinet.

Practical Recommendations

- Open the control cabinet and inspect visually every 6–12 months

- Use a vacuum and compressed air to clean dust, chips, and oil residue

- Install filter mats on ventilation inlets

- Keep ambient temperatures below 45 °C

- Plan for fan replacement intervals every 2–3 years depending on environment

- If possible, monitor internal temperature with sensors or thermography

Conclusion

Even modern drives like the MDS-CH-V2-4535 are vulnerable to neglect. Contamination is the silent killer of servo and spindle drives.

With just a little attention to cleanliness and preventive maintenance, most early failures can be avoided.

Because in industrial electronics, as in life:

Prevention is better than cure.

To mentioned Mitsubishi Drive: Mitsubishi Servo Drive MDS-CH-V2-4535

Similar type MDS-C1-V2-4535

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Summary of the Unit

| Parameter | Value |

|---|

| Model | MDS-CH-V2-4535 |

| Voltage Class | 400 V |

| Input Power | 3PH AC 513–648V, 50/60 Hz 10,1 A |

| Output Current | ca. 1x 11 A 1x 8,4A

3PH 456V 0-240Hz

4,5-3,5 KW |

| Cooling | Air-cooled |

| Weight | Approx. 7–9 kg |

Operating Environment

- Designed for CNC machine tools (e.g., milling, turning, grinding centers)

- Compatible with Mitsubishi CNC controls (e.g., MELDAS M70/M700)

- Suitable for Mitsubishi servo motors like HC- or HA-series

- Ambient temperature inside control panel: Max. 55 °C

- Proper grounding required

- Keep away from oil mist, excessive vibration, and EMI sources

Functional Description

The MDS-CH-V2-4535 is a dual-axis AC servo amplifier designed for precision motion control in CNC systems. Its main functions include:

- Controlling two servo motors independently

- Executing high-speed and high-precision positioning

- Supporting absolute or incremental encoders

- Adaptive gain control and filtering (SHG, notch filter)

- Built-in protection, diagnostics and error logging

- Status indication via front LEDs and CNC interface

Alarm List & Troubleshooting Examples

| Alarm No. | Description | Likely Cause and Solution |

|---|

| 11 | Axis Selection Error | Duplicate or invalid axis number → check rotary switch |

| 17 | A/D Converter Error | A/D IC failure → replace drive unit |

| 18 | Initial Communication Failure (Encoder) | Faulty cable or detector → check/replace CN2/CN3 cables |

| 50 | Overload | High load, short accel time → check SV022, gain, brakes |

| 58 | Collision Detection (Rapid) | Torque limit exceeded → review SV060 and tuning |

| 93 | Absolute Position Fluctuation | Battery low or connection issue → inspect and replace |

Internal Components

| Name | PCB Code(s) | Quantity |

|---|

| Control Board | RK112A-12 or BN634A980G51 B | 1 |

| Power Board | RK163B-V2-4535 or BN638A289G51 Ж | 1 |