08.09.2025 by Viktor Siebert

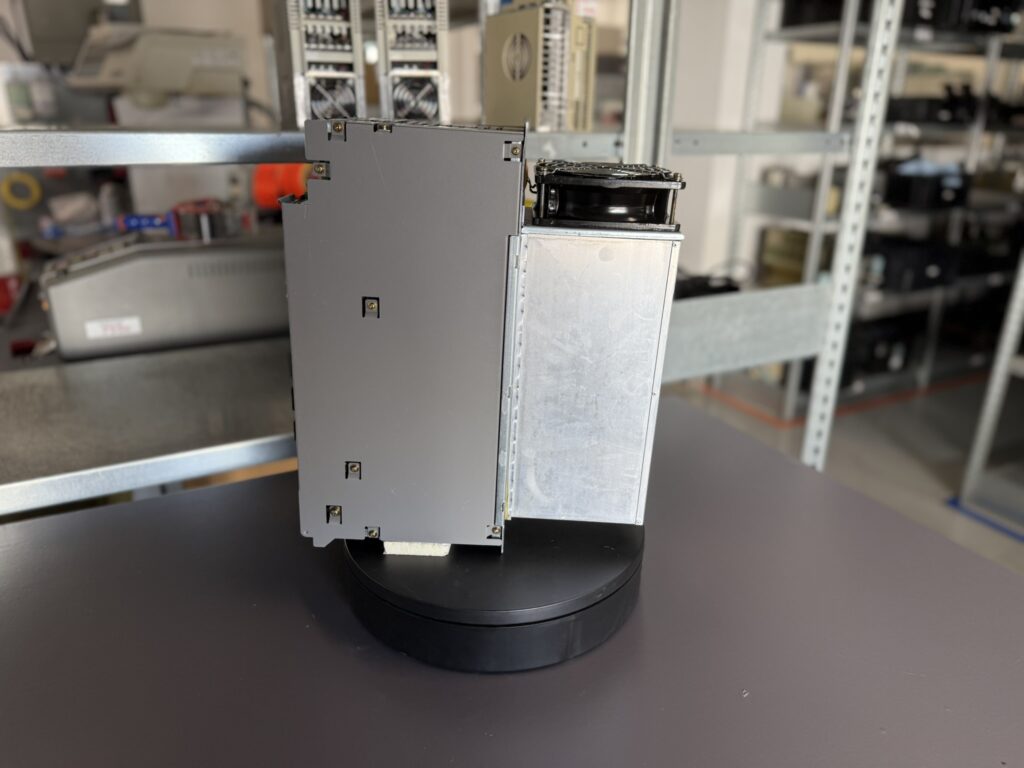

Okuma Power Supply MPS30 1006-2202 Repair and Preventive Measures

The MPS30 unit was sent in with the following description:

After powering up, the unit starts normally, and the DC bus voltage of 300 V is stable. However, after about five seconds, the controller shuts down. The power supply itself indicates error code 04 (Main Circuit Power Error), while the connected axes show code 07.

To confirm the issue, the device was tested on our MTest bench, which allows operation under realistic load conditions. The fault was reproduced reliably: after initialization, the system dropped out with the described errors.

Analysis and Repair Steps:

- Visual Inspection and Cleaning: The housing was covered with dust and oil deposits. A thorough ESD-safe cleaning was carried out.

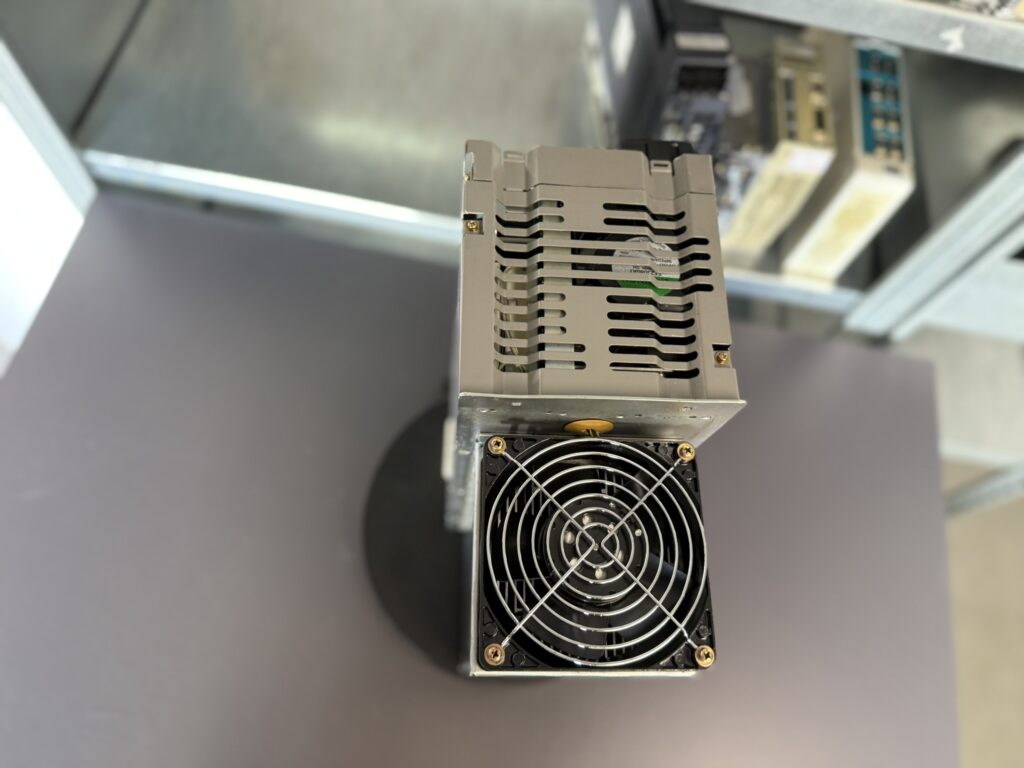

- Preventive Replacement: All electrolytic capacitors were replaced due to natural aging under thermal stress. ICs, Fans and relay contacts were also renewed.

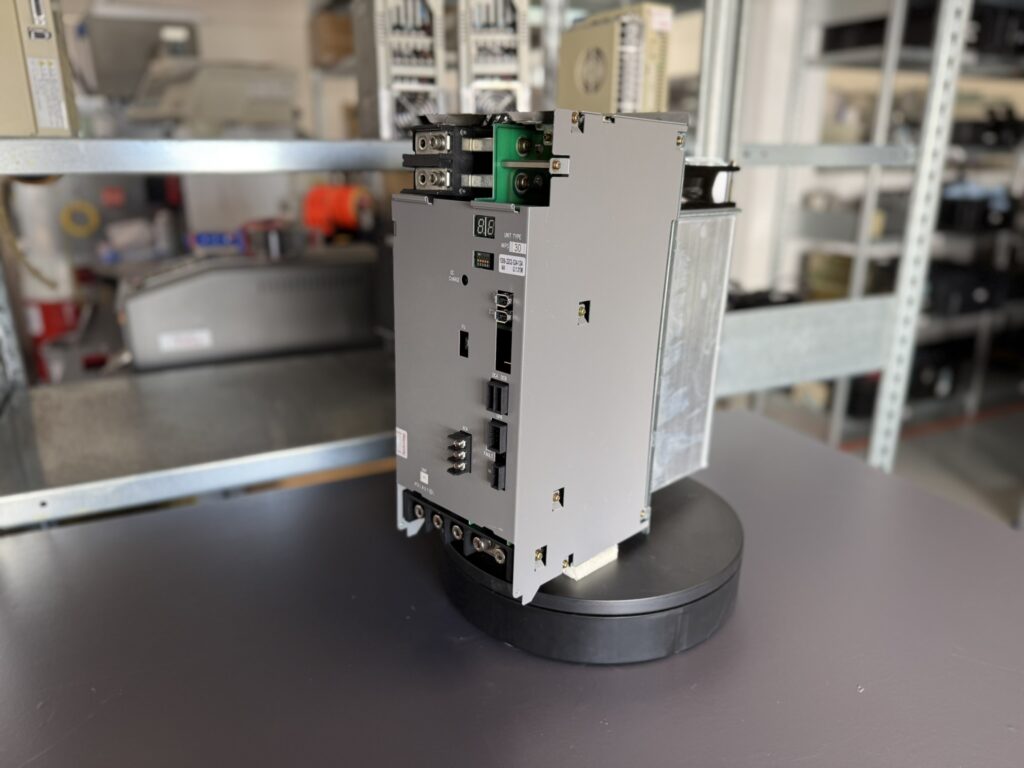

- Control Circuit Diagnosis: The PSB board showed unstable +12 V and -12 V supplies, causing error code 07 on the axes. Faulty regulator ICs were replaced, restoring voltage stability.

- Power Stage Testing: Load tests with simulated axis and spindle currents were conducted. The IGBT modules behaved normally under thermal stress.

- Thermal Stress Test: The device was run for several hours under varying load cycles to ensure stability.

- Documentation: All steps were logged in detailed checklists. Voltage levels, current traces, and temperatures were recorded.

The unit passed all tests successfully and was returned to the customer in stable, fault-free condition, eliminating the need for costly replacement.

Preventive Measures for Customers

To extend the lifetime of the MPS30, we recommend:

- Regular cleaning of the cabinet and cooling ducts

- Fan replacement every 2–3 years

- Insulation testing during machine downtime

- Inspection of seals to prevent dust and oil ingress

- Temperature monitoring to avoid overheating

Conclusion

The Okuma MPS30 is a powerful supply module that contributes significantly to energy efficiency through regeneration. However, in practice, failures often occur due to overheating, aged capacitors, or faulty control circuits. Professional repair combined with preventive maintenance extends service life and reduces machine downtime.

For more information about our Okuma repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Okuma drive technology. Our experienced team is always ready to provide you with expert advice and support.

Technical Specifications (Device Data):

| Parameter | Value |

|---|

| Model | Okuma MPS30 (1006-2202) |

| Type | Power Regeneration DC Power Supply Unit |

| Rated Power | 30 kW (40 HP) |

| Input Voltage | 200 VAC (3-phase) |

| Output Voltage | 300 VDC (DC bus), 24 VDC (control) |

| Weight | 11.8 kg |

| Dimensions (H × W × D) | 380 × 150 × 325 mm |

| Main Components | Control board PSB-MPS30, Display card MFP1, Power Unit MPS30 PU, AC Choke MPS30-ACL |

Application Environment & Compatible Devices

The MPS30 is used in CNC machines equipped with spindle drives that require energy regeneration into the mains. It is typically found in Okuma lathes and machining centers, often paired with MIV servo amplifiers. Thanks to its capacity, it is well-suited for machines with high energy demands.

Functional Description

The MPS30 functions as a DC power supply unit for Okuma motion control systems. It provides the 300 VDC bus voltage for MIV amplifiers as well as the 24 VDC control voltage.

The key feature of the MPS series is energy regeneration: excess braking energy from the motors is fed back into the power grid instead of being dissipated via resistors. This saves energy and reduces thermal stress inside the cabinet.

Alarm Messages and Troubleshooting

| Error Code | Description | Cause | Solution |

|---|

| 01 | DC Overvoltage | DC bus voltage too high | Check power supply, replace unit |

| 02 | DC Undervoltage | DC bus voltage too low | Check power supply, replace unit |

| 03 | Open Phase | Missing or distorted input phase | Verify mains, replace unit |

| 04 | Main Circuit Power Error | Error in input voltage | Verify mains, replace unit |

| 05 | Control Power +5V Error | Voltage out of tolerance | Check/replace unit |

| 06 | Control Power +12V Error | Voltage out of tolerance | Check/replace unit |

| 07 | Control Power -12V Error | Voltage out of tolerance | Check/replace unit |

| 08 | Overcurrent in Power Cable | Abnormal current detected | Check cables, replace unit |

| 09 | Power Device Error (IPMF) | Fault in power module | Replace unit |

| 10 | Converter Bridge Short Circuit | Short circuit in power device | Inspect cables/module |

| 13 | Heatsink Overheat | Excessive temperature | Check fans, replace unit |

Components

| Type (DE) | Model Name | Manufacturer No. | Description |

|---|

| Control Board | PSB-MPS30 | 1006-2104 | Control board for MPS20 to MPS60 |

| Display Card | MFP1 CARD | 1006-2105 | Status display and indicators |

| Power Module | MPS30 PU | 1006-2202 | 30 kW (40 HP) Power Unit |

| AC Reactor | MPS30-ACL | 1006-2282 | AC choke with capacitor |