12.09.2025 by Viktor Siebert

Yaskawa AC Spindle Motor UAASKD-08LYA11 Precision and Reliability in Machining

The Yaskawa AC spindle motor UAASKD-08LYA11 reached our workshop not directly from the end customer, but through a motor service company that had already carried out a preliminary inspection. The end customer, a mid-sized machining company, reported extreme bearing noise during operation so loud that operators were forced to wear hearing protection. This clearly indicated that the high-precision spindle bearings, designed for high speeds and continuous load, were worn or damaged. Continuing operation in this state was not only an acoustic burden but could also lead to severe secondary damage to the rotor or windings.

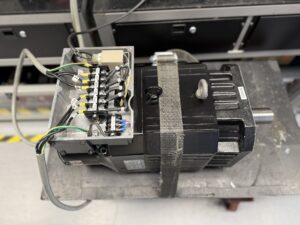

Upon arrival, we performed an initial inspection. The housing showed heavy contamination, traces of coolant, and fine metallic dust typical for demanding machining environments. Insulation resistance was still within limits, but the contamination would have eventually led to failure. A complete overhaul was therefore essential.

Disassembly revealed the full extent of the damage: the bearings showed clear wear marks, uneven running, and audible rattling. Since these bearings are rated for up to 10,000 rpm, even small defects result in resonance, noise, and overheating. There were also signs of localized overheating at the bearing seat, evidence that the motor had been run too long despite the defect.

Parallel to the mechanical inspection, we analyzed the UTMSI-10AAGAZA encoder. It exhibited drift errors at low speeds, meaning feedback signals did not match actual spindle movement. In CNC operation, such drift can cause tool clamping failures, positioning errors, and faulty reference moves. Especially during slow-speed tool changes, this poses a serious risk for production quality.

The repair process began with complete cleaning in an emulsion bath, followed by oven drying to eliminate all moisture. The rotor was dynamically balanced to minimize vibration. Bearings were replaced with new precision-grade units, and all seals were renewed to prevent future ingress of coolant or dust. Electrical connectors were cleaned and partly replaced to eliminate possible contact issues.

One of the most critical steps was the encoder replacement and calibration. Even slight misalignment can lead to faulty signals. After installing the new encoder, it was electronically programmed and fine-adjusted. Using specialized testing equipment, we monitored real-time signal quality until it met all specifications.

After reassembly, the motor was tested on our Yaskawa M5 test bench. First, idle operation was checked for noise, vibration, and current draw. Then, load tests were conducted at different speeds, accelerations, and sudden load changes. Throughout, the encoder signals were monitored to confirm correct operation.

The motor then went through a break-in process, gradually adapting the new bearings to operating conditions. Only after this phase was the motor released as fully operational.

The result: a spindle motor running smooth, quiet, and precise, ready for heavy-duty CNC use. The end customer reported significant improvements in machine behavior quieter operation, better surface finish, and improved working comfort for the operators.

Causes of Encoder or Motor Failures

- Encoder: temperature changes, moisture, oil mist, vibration, cable wear, aging

- Motor: overload, inadequate cooling, bearing wear, contamination

Failures often develop gradually:

sporadic alarms → irregular disturbances → more frequent errors → complete breakdown.

Preventive Tips for Customers

- Regularly inspect cables and connectors

- Keep environment clean and dry

- Prevent oil and dust ingress

- Avoid sudden temperature fluctuations

- Plan preventive overhauls every 3–5 years

Further information such as price and delivery time for the: Yaskawa AC Spindle Motor UAASKD-08LYA11

More details about our Yaskawa repair expertise can be found here: Yaskawa Repair at Industrypart

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology.

Our team looks forward to your inquiry!

Technical Specifications

| Feature | Value |

|---|

| Motor Type | Yaskawa AC Spindle Motor UAASKD-08LYA11 |

| Power | 7,5 kW |

| Rated Voltage | 220 V AC |

| Rated Current | 36 A |

| Max. Speed | 10,000 min⁻¹ |

| Phases | 3 |

| Frequency | 200 Hz |

| Number of Poles | 4 |

| Protection Class | IP54 (typical for spindle motors) |

| Insulation Class | F |

| Encoder | Yaskawa UTMSI-10AAGAZA (magnetic incremental encoder) |

| Weight | approx. 80–100 kg (depending on build size) |

Application Environment & Compatible Devices

The UAASKD-08LYA11 is used in CNC machine tools, particularly in lathes and machining centers, where high rotational speeds and precise torque control are required.

Typical applications:

- Metalworking (milling, turning, drilling)

- High-speed cutting

- Automated production lines

Compatible drives/inverters:

- Yaskawa CIMR-M5 Inverter (M5 series)

- Yaskawa CIMR-MR5 Converter (in combination with spindle controllers)

Functional Description

The spindle motor converts electrical energy into high-precision rotational motion. Thanks to the UTMSI encoder, exact position and speed information is provided to the drive system.

Key features:

- High dynamics during tool changes

- Precise positioning for tool clamping

- Stable performance at high speeds

- Robust design for industrial environments

Alarm Messages & Troubleshooting

Based on Yaskawa M5 inverter fault codes

| Alarm No. | Description | Cause | Solution |

|---|

| AL-01 | Overcurrent | Short-circuit, excessive load | Check wiring, remove short-circuit |

| AL-02 | Ground fault | Insulation failure in motor/windings | Check insulation, cables |

| AL-04 | Main fuse blown | Transistor defect, load-side short | Replace fuse, inspect transistors |

| AL-05 | Inverter overload | Load >120% rating | Reduce load, check mechanics |

| AL-06 | Motor overload | Excessive continuous load | Reduce load, check lubrication |

| AL-07 | Motor locked | Tool jammed, bearing damage | Free shaft, inspect bearings |

| AL-12 | DC undervoltage | Supply voltage too low | Check input voltage |

| AL-30 | Encoder signal fault | Broken cable, loose connector | Inspect encoder wiring |

| AL-31 | Overspeed | Speed >120% of set value | Adjust parameters, check encoder |

| AL-40 | Motor overheating | Cooling failure, ambient temperature | Clean fan, improve airflow |

Components

| Component | Description |

|---|

| Rotor | Precision shaft, dynamically balanced |

| Stator | Winding assembly with thermal protection |

| Encoder | UTMSI-10AAGAZA, magnetic incremental encoder |

| Bearings | High-speed precision ball bearings |

| Housing | Robust aluminum/steel casing, painted |

| Seals | Protection against dust, oil mist, coolant |

| Connectors | Power and signal connectors |