27.06.2025 by Viktor Siebert

A Look Inside Our Workshop: How We Test Your Repaired Servopacks Yaskawa SGDV-5R5A01A

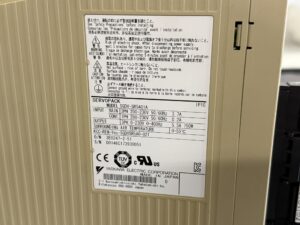

Recently, we received a Yaskawa Servopack SGDV-5R5A01A for repair, showing the error A.100 (Overcurrent / Heatsink Overtemperature). While this may seem like a routine case, we treat every device with the same care and diligence as the original manufacturer.

What appears to be a standard repair on the surface requires expertise, experience, and a well-structured testing process behind the scenes.

What exactly do we do?

For this device, we carried out the following work:

- Replacement of the power stage (IGBT section)

- Replacement of the gate driver module

- Renewal of all DC link capacitors

- Cleaning, visual inspection, and renewal of the thermal compound

- Replacement of the cooling fan

- Re-soldering of thermally stressed joints (hotspots)

Our Test Bench: Developed In-House – Tested Like the Manufacturer

To ensure the quality of our repairs, we developed our own test racks for Sigma-5 Servopacks over seven years ago. These simulate real-world conditions with various load profiles and control scenarios.

What happens during testing?

- Initial power-up check: Voltage, current draw, encoder feedback

- Partial load testing: Analog input response, ramping, braking function

- Full load testing with simulated motor operation: Continuous run >30 minutes

- Fault simulation and safety checks: Triggering and verifying protective shutdowns

- Final test with log documentation: All parameters recorded and compared to factory specs

We test using the same standards applied by the manufacturer – in some cases even enhanced with our own tools to better detect latent faults.

Transparency Builds Trust

We created a short video for this repair that showcases our test setup. We don’t just want to say we do quality work – we want to show it. Transparency is a core value of our company and one of the key reasons many customers choose to work with us long-term.

Conclusion: Even though error A.100 is a relatively common fault in Yaskawa SGDV devices, we approach every repair with technical precision, perform in-depth testing, and document everything clearly.

If your device is showing an error – feel free to get in touch with us.

Information about the mentioned Servopack: Yaskawa Servopack SGDV-5R5A01A

For more details about our Yaskawa repair services, visit: Yaskawa Sigma V Repairs

📞 Feel free to contact us if you have any questions about your Yaskawa drive technology!

Technical Device Data

| Parameter | Value |

|---|

| Model | SGDV-5R5A01A |

| Input (MAIN) | 3PH 200–230 V, 50/60 Hz, 3.7 A |

| Control Power (CONT) | 1PH 200–230 V, 50/60 Hz, 0.2 A |

| Output | 3PH 0–230 V, 0–400 Hz, 5.5 A, 750 W |

| Ambient Temperature | 0–55 °C |

| Protection Class | IP10 |

| Manufacturer | Yaskawa Electric Corporation, Japan |

Internal Components

| Component | PCB Label | Qty |

|---|

| Control Board | SGDV-IFA01B | 1 |

| Power Board | SGDV-CB7R6AAB | 1 |

Operating Environment & Compatibility

The SGDV-5R5A01A belongs to the Sigma-5 series and features an analog/pulse interface. It is compatible with:

- SGMJV, SGMAV, SGMGV, SGMPS, SGMSV, SGMCS servo motors.

Typical applications:

- High-speed, high-precision positioning tasks

- Systems with variable mechanical loads

- Machines requiring real-time encoder feedback

Environmental specs:

- Operating temp: 0–55 °C

- Storage temp: -20–85 °C

- Humidity: ≤ 90%, non-condensing

- Max altitude: 1000 m above sea level

Functional Description

The SGDV-5R5A01A Servopack supports:

- Speed control (V-mode)

- Position control (P-mode)

- Torque control (T-mode)

Features include:

- Speed control ratio of 1:5000

- Analog inputs ±12 V for V- and T-mode

- Pulse input (up to 4 Mpps with line driver)

- Encoder output: A/B/C phase (line driver)

- Adjustable smoothing & zero offset

- Parameter-based brake resistor configuration (Pn600)

Alarm List (Excerpt)

| Code | Description | Countermeasure |

|---|

| A.100 | Overcurrent / Heatsink Overtemperature | Check wiring, rule out short circuits, replace SERVOPACK if needed |

| A.300 | Regeneration error | Check wiring and value of brake resistor, verify Pn600 |

| A.320 | Regeneration overload | Increase brake resistor rating, correctly configure Pn600 |

| A.400 | Overvoltage | Check supply voltage, install surge suppressors if needed |

| A.410 | Undervoltage | Check grid voltage and stability, adjust Pn509 if required |

| A.830 | Absolute Encoder Battery Fault | Check or replace battery |

| A.C90 | Encoder communication failure | Inspect encoder wiring, grounding, and connectors |

| A.CC0 | Multiturn limit mismatch | Check Pn205, correct with Fn013 if necessary |