11.09.2025 by Viktor Siebert

Express Repair of a Yaskawa SGDS-02A12AY27 Servopack within 24 Hours

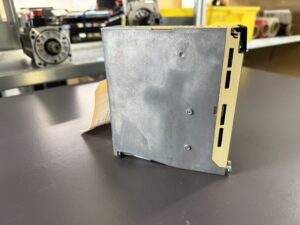

The Yaskawa SGDS-02A12AY27 Servopack described here was sent to our workshop as an urgent repair case. The customer reported that the unit showed no function at all. Since the machine was crucial for production, extended downtime would have caused severe disruptions. Therefore, a 24-hour turnaround was requested.

Upon arrival, we immediately carried out a structured failure diagnosis. During the initial inspection, we noted that none of the status LEDs were responding. This strongly indicated a failure of the power supply circuit or a defect in the power module.

We opened the unit and performed a detailed visual inspection. Dust deposits and initial signs of thermal stress on the power board were clearly visible. The unit was carefully cleaned with anti-static tools to eliminate any risk of conductive dust particles causing shorts.

Next, we tested the IGBT power semiconductors and capacitors using specialized measuring equipment. Several capacitors had lost significant capacitance, and one IGBT module had failed. These parts were replaced. Additionally, we carried out a preventive replacement of other aged components that are known to fail after many years of operation.

One of our core practices is to follow structured checklists and to document every step of the process. This ensures transparency for the customer and avoids overlooking critical details.

After reassembly, the unit underwent intensive testing on our in-house test bench. It was connected to a suitable 200 W servomotor and operated under various modes: idle, dynamic load changes, and continuous operation at rated speed. To ensure long-term stability, we also carried out a thermal stress test where the unit was run for several hours under elevated temperature conditions.

All tests were passed successfully. The Servopack was repaired, tested, and returned to the customer within 24 hours. This minimized downtime and enabled the customer to quickly resume production.

Preventive Measures for the Customer

To extend the service life of a Yaskawa SGDS Servopack, we recommend:

- Regular cleaning to remove dust and debris.

- Fan replacement at fixed intervals, as fans are a common failure point.

- Insulation measurements on motors and cables to detect early damage.

- Inspection of seals and connectors to avoid corrosion or moisture ingress.

- Proper ventilation of control cabinets to reduce thermal stress.

Conclusion

The Yaskawa SGDS-02A12AY27 Servopack is a reliable unit for precise drive tasks in automation and machinery. Our repair experience shows that even in cases of complete failure, fast recovery is possible through systematic diagnostics, preventive replacement of critical parts, and thorough testing. This ensures minimal downtime and maximum operational safety for the customer.

For further details such as pricing and delivery times regarding the Yaskawa SGDS-02A12AY27 Servopack

For more information about our Yaskawa repairs, please click here.

📞 Please feel free to contact us with any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Technical Profile:

| Specification | Value |

|---|

| Model | SGDS-02A12AY27 (Sigma III series) |

| Rated power | 200 W |

| AC input | Single-phase 200–230 V, 50/60 Hz, 2.4 A |

| AC output | Three-phase 0–230 V, 0–300 Hz, 2.1 A |

| Protection class | IP1X |

| Operating temperature | 0–55 °C |

| Weight | approx. 1.5–2.0 kg (depending on version) |

| Dimensions (HxWxD) | approx. 150 x 65 x 130 mm (typical for the series) |

| Interface | MECHATROLINK-II + Serial fully-closed interface (Code 12) |

| Origin | Made in Japan |

Operating Environment & Compatible Devices

The SGDS-02A12AY27 Servopack is part of the Yaskawa Sigma III series. Typical application areas include CNC machines, packaging equipment, textile machines, handling systems, and automation solutions with high demands on dynamics and precision.

Compatible devices are Yaskawa Sigma III motors with a rated power of 200 W. Thanks to the MECHATROLINK-II interface, the unit can be easily integrated into existing control systems.

Functional Description

The Servopack controls and regulates the connected servomotor. It converts the supply voltage into a precisely regulated three-phase output and ensures exact speed, torque, and position control of the motor.

Key features:

- MECHATROLINK-II fieldbus for fast communication.

- Vector control for precise positioning.

- Comprehensive protection and diagnostic functions.

- Thermal monitoring to ensure operational safety.

Alarm Messages and Troubleshooting

Extract from the manual

| Alarm Code | Alarm Name | Meaning |

|---|

| A.020 | Parameter Checksum Error 1 | Parameter data in the SERVOPACK is incorrect. |

| A.021 | Parameter Format Error 1 | Parameter data format in the SERVOPACK is incorrect. |

| A.022 | System Parameter Checksum Error 1 | System-parameter data in the SERVOPACK is incorrect. |

| A.023 | Parameter Password Error 1 | Parameter password/protection error; parameter data invalid. |

| A.02A | Parameter Checksum Error 2 | Parameter data in the SERVOPACK is incorrect (variant 2). |

| A.02B | System Parameter Checksum Error 2 | System-parameter data in the SERVOPACK is incorrect (variant 2). |

| A.030 | Main Circuit Detector Error | Detection data for the power circuit is incorrect. |

| A.040 | Parameter Setting Error 1 | Parameter setting is outside the allowable range. |

| A.044 | Parameter Setting Error 2 | Parameter setting remains outside the allowable range. |

| A.041 | Dividing Pulse Output Setting Error | PG dividing pulse (Pn212) out of range or setting conditions not satisfied. |

| A.050 | Combination Error | SERVOPACK and servomotor capacities do not match. |

| A.100 | Overcurrent or Heat Sink Overheated | Overcurrent flowed through IGBT or SERVOPACK heat sink overheated. |

| A.300 | Regeneration Error Detected | Fault in regenerative circuit or regenerative resistor. |

| A.320 | Regenerative Overload | Regenerative energy exceeds the capacity of the regenerative resistor. |

| A.330 | Main Circuit Power Supply Wiring Error | Power supply to main circuit does not match parameter Pn001 setting. |

| A.400 | Overvoltage | Main circuit DC voltage is excessively high. |

| A.410 | Undervoltage | Main circuit DC voltage is excessively low. |

| A.510 | Overspeed | Motor speed is excessively high. |

| A.511 | Dividing Pulse Output Overspeed | Upper speed limit of the set PG dividing pulse (Pn212) is exceeded. |

| A.520 | Vibration Alarm | Vibration at the motor speed detected. |

| A.710 | Overload: High Load | Motor operated for several to several tens of seconds at torque largely exceeding ratings. |

| A.720 | Overload: Low Load | Motor operated continuously at torque largely exceeding ratings. |

| A.730 | Dynamic Brake Overload | During dynamic braking, rotational energy exceeded the brake resistor capacity. |

| A.740 | Overload of Surge Current Limit Resistor | Main circuit power was frequently turned ON and OFF; inrush-limit resistor overloaded. |

| A.7A0 | Heat Sink Overheated | SERVOPACK heat sink overheated. |

Components

| Module / Part | Description |

|---|

| Control board | Implements regulation algorithms and communication |

| Power module | IGBTs for converting supply into motor output |

| Line filter | Suppression of electrical interference |

| Capacitor bank | Smoothing of the DC bus voltage |

| Heat sink & fan | Thermal stability |

| Terminal blocks | Connections for motor, power, and signal cables |